BOPP jumbo roll tape is commonly used for packaging, sealing, and various industrial applications. The manufacturing of BOPP jumbo roll tape involves several key processes:

Polymer Extrusion:

The process begins with the extrusion of polypropylene resin pellets. The polymer is melted and then extruded through a flat die to form a thin film.

Film Orientation (Biaxial Stretching):

The extruded film is then biaxially stretched, both in the machine direction (MD) and the transverse direction (TD). This stretching enhances the mechanical and optical properties of the film, making it stronger and clearer.

Corona Treatment:

To improve the adhesion of inks and coatings, the BOPP film is subjected to corona treatment. This process increases the surface energy of the film, allowing for better printing and coating.

Coating and Primer Application:

A primer layer is applied to the BOPP film to enhance the adhesion of subsequent coatings. Adhesive coatings are then applied to one side of the film to create the sticky side of the tape.

Drying:

The coated BOPP film passes through drying ovens to remove solvents from the adhesive and coatings. This ensures that the tape is dry and ready for further processing.

Slitting:

The wide coated BOPP film, known as a jumbo roll, is then slit into narrower rolls of the desired width. This is often done using precision slitting machines.

Rolling and Packaging:

The slit rolls are wound onto cores to create the finished product. The rolls are then packaged and prepared for distribution.

Printing (Optional):

If branding, logos, or other information is required on the tape, printing can be performed after the corona treatment. Flexographic or gravure printing methods are commonly used for this purpose.

Quality Control:

Throughout the manufacturing process, quality control measures are implemented to ensure that the tape meets the specified standards. This may include testing for adhesive strength, film thickness, and visual inspection.

It's important to note that the specific details of the manufacturing process can vary among different manufacturers and the desired characteristics of the final product. Additionally, some BOPP tapes may undergo additional processes, such as the application of release liners or the inclusion of special features like reinforced fibers for added strength.

Web Menu

Product Search

Exit Menu

What Are the Key Manufacturing Processes Involved in Producing Bopp Jumbo Roll Tape?

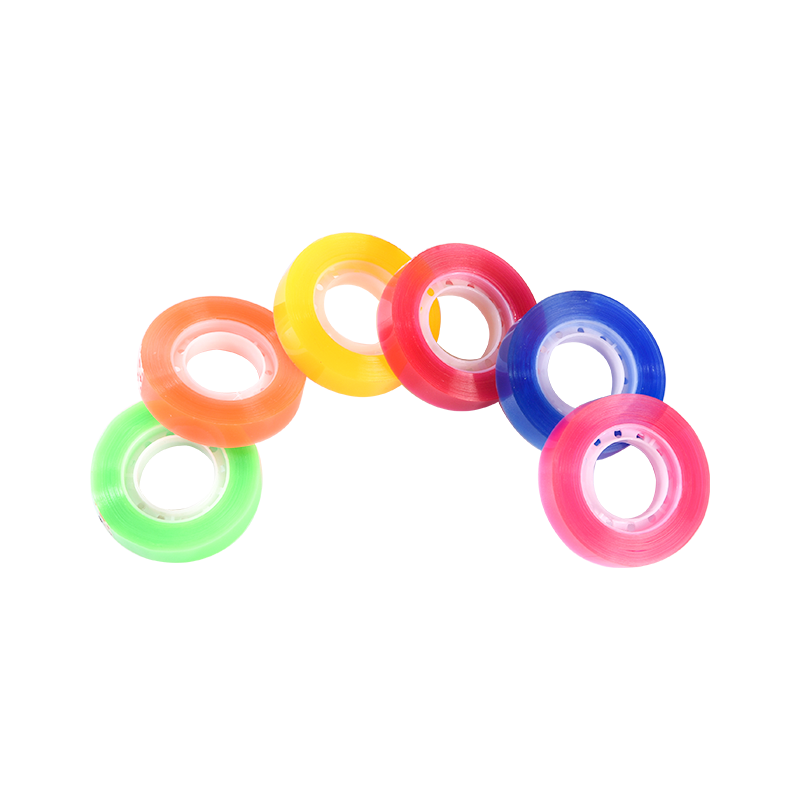

Recommended Products

Product Categories

Recommended Products

Copyright © Zhejiang Jinke Adhesive Products Co., Ltd. All Rights Reserved Wholesale Adhesive Products Manufacturers

EN

EN  English

English 中文简体

中文简体